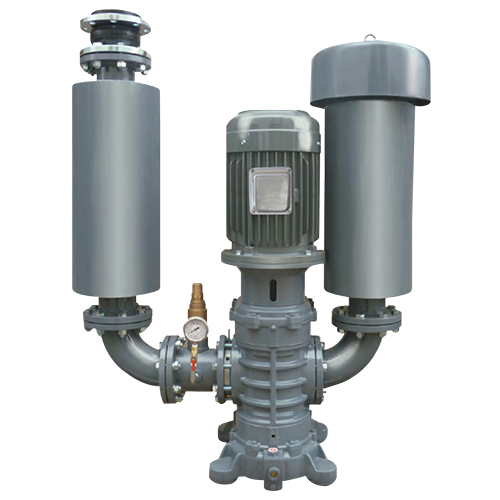

Sanco Vertical Air Blower Silent type

Product Line

ENERGY SAVING, CARBON REDUCTION

HIGN EFFICIENCY AND SPACE SAVER

SANCO SCD SERIES

Performance

Sanco Vertical Air Blower SCD Series Silent Type

Bore Size: 40mm ~ 150mm (1.5″ ~ 6″)

Capacity: 0.4 ~ 22 m/min ( 24 ~1320 m/hr)

Pressure: 0~ 6000 mmAq (0~0.6 kgf/cm)

Advantage

Tri-Lobe Roots Blower

Air cooled and circulated for whole blower.

- Silent type which generates lower noise than standard root blower

- Extreme low vibration

- Saving electricity

- High efficiency

- Vertical type designed saves space

- Stable construction

- Maintenance easily

- Cleaner air with Oil free operation

- Coupling driven without belt

Application

- Waste Water Treatment

- Aquaculture

- Electroplating Industry

- Powder Conveyance

- Grain Conveyance

- Paper Production

- Food Industry

- Semiconductor Industry,

- Chemical Industry…etc.

- Especially suitable to install in Hospital

- School

- Hotel

- ResidentialArea

- Office Building where needed low noise.

SPECIFICATIONS

PERFORMANCE

TABLE Suction Air & Discharge Pressure

| Silent Roots Blower | 50HZ-4P | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Motor | Bore (mm) |

Performance table Qs (m3/min) PRESSURE (mmH2O) La (Kw) | ||||||||||

| 1000 (mmH2O) | 2000 (mmH2O) | 3000 (mmH2O) | 4000 (mmH2O) | 5000 (mmH2O) | 6000 (mmH2O) | ||||||||

| Qs | La | Qs | La | Qs | La | Qs | La | La | Qs | La | |||

| SCD40 | 1.5Kw. | 40 | 1.18 | 0.72 | 0.96 | 1 | 0.79 | 1.28 | - | - | - | - | - |

| 2.2Kw. | 40 | 1.18 | 0.72 | 0.96 | 1 | 0.79 | 1.28 | 0.65 | 1.58 | 0.53 | 0.41 | 2.11 | |

| SCD50 | 1.5Kw. | 50 | 1.59 | 0.81 | 1.34 | 1.17 | - | - | - | - | - | - | - |

| 2.2Kw. | 50 | 1.59 | 0.81 | 1.34 | 1.17 | 1.15 | 1.53 | 0.98 | 1.89 | - | - | - | |

| 3.7Kw. | 50 | 1.59 | 0.81 | 1.34 | 1.17 | 1.15 | 1.53 | 0.98 | 1.89 | 0.84 | 0.71 | 2.61 | |

| SCD65 | 2.2Kw. | 65 | 2.17 | 0.94 | 1.82 | 1.43 | 1.56 | 1.92 | - | - | - | - | - |

| 3.7Kw. | 65 | 2.17 | 0.94 | 1.82 | 1.43 | 1.56 | 1.92 | 1.34 | 2.41 | 1.14 | 0.97 | 3.39 | |

| SCD80 | 3.7Kw. | 80 | 4.75 | 1.58 | 4.28 | 2.54 | 3.92 | 3.5 | - | - | - | - | - |

| 7.5Kw. | 80 | 4.75 | 1.58 | 4.28 | 2.54 | 3.92 | 3.5 | 3.62 | 4.46 | 3.35 | - | - | |

| 3.7Kw. | 80 | 4.75 | 1.58 | 4.28 | 2.54 | 3.92 | 3.5 | 3.62 | 4.46 | 3.35 | 3.11 | 6.39 | |

| SCD100 | 7.5Kw. | 100 | 5.9 | 1.82 | 5.32 | 3.01 | - | - | - | - | - | - | - |

| 7.5Kw. | 100 | 5.9 | 1.82 | 5.32 | 3.01 | 4.88 | 4.21 | 4.5 | 5.4 | - | - | - | |

| 15Kw. | 100 | 5.9 | 1.82 | 5.32 | 3.01 | 4.88 | 4.21 | 4.5 | 5.4 | 4.17 | - | - | |

| SCD125 | 5.5Kw. | 125 | 9.53 | 2.93 | 8.91 | 4.74 | - | - | - | - | - | - | - |

| 5.5Kw. | 125 | 9.53 | 2.93 | 8.91 | 4.74 | 8.43 | 6.54 | - | - | - | - | - | |

| 5.5Kw. | 125 | 9.53 | 2.93 | 8.91 | 4.74 | 8.43 | 6.54 | 8.03 | 8.35 | 7.67 | - | - | |

| 11Kw. | 125 | 9.53 | 2.93 | 8.91 | 4.74 | 8.43 | 6.54 | 8.03 | 8.35 | 7.67 | 7.35 | 11.96 | |

| 0.75kW=1HP, 1.5kW=2HP, 2.2kW=3HP, 3.7kW=5HP, 5.5kW=7.5HP, 7.5kW=10HP 11kW=15HP, 15kW=20HP, 18.5kW=25HP, 22kW=30HP, 30kW=40HP, 37kW=50HP |

|||||||||||||

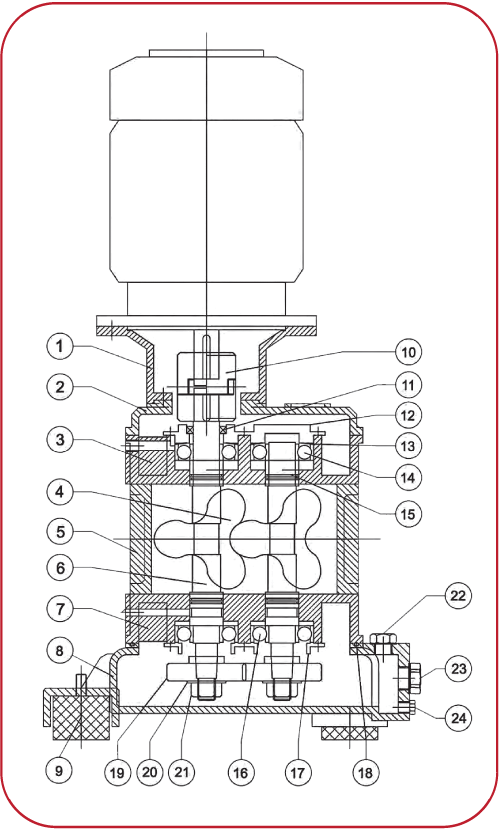

STRUCTURE & MATERIAL LIST

| No. | Name | Material |

|---|---|---|

| 1 | MOTER CASE | FC250 |

| 2 | OIL TANK | FC250 |

| 3 | SIDE COVER | FC250 |

| 4 | ROTAR | FC250 |

| 5 | MAIN BODY | FC250 |

| 6 | SHAFT | SCM440 |

| 7 | SIDE COVER | FC250 |

| 8 | OIL TANK | FC250 |

| 9 | ABSORBER | NBR |

| 10 | COUPLING | FC200 |

| 11 | OIL SEAL | NBR |

| 12 | BEARING COVER | S45C |

| 13 | DISE SPRING | SS400 |

| 14 | BEARING | SUJ2 |

| 15 | LABYRINTH SEAL | S45C |

| 16 | BEARING | SUJ2 |

| 17 | BEARING COVER | S45C |

| 18 | O RING | NBR |

| 19 | GEAR | SCM415 |

| 20 | WASHER | S45C |

| 21 | NUT | S45C |

| 22 | OIL PLUG | S45C |

| 23 | OIL GAUGE | S45C |

| 24 | OIL DRAIN | S45C |

Unit Conversion

Pressure

| Kgf/cm2 | kPa | mbar | psi | mmAq mmH2O |

Torr mmHg |

|---|---|---|---|---|---|

| 1 | 98.0665 | 980.665 | 14.2231 | 10,000 | 735.559 |

| 0.010197 | 1 | 10 | 0.145 | 101.9716 | 7.50062 |

| 0.001019 | 0.1 | 1 | 0.0145 | 10.19716 | 0.750062 |

| 0.07031 | 6.895 | 68.95 | 1 | 703.08 | 51.7157 |

| 0.0001 | 0.009806 | 0.098 | 0.001422 | 1 | 0.073556 |

| 0.00136 | 0.13332 | 1.33321 | 0.019336 | 13.5951 | 1 |

Power

| CMM (m3/min) | CFM (ft3/min) | LPM (I/min) |

|---|---|---|

| 1 | 35.32 | 1000 |

| 0.0283 | 1 | 28.3125 |

| 0.001 | 0.0353 | 1 |

Capacity

| kW | HP | PS |

|---|---|---|

| 1 | 1.3404 | 1.3596 |

| 0.746 | 1 | 1.0143 |

| 0.7355 | 0.5859 | 1 |